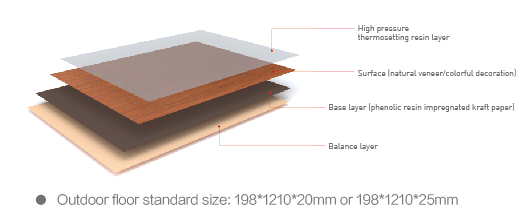

- Outdoor flooring

- Outdoor furniture board

- Outdoor decorative grille panel

- High pressure laminate wood fiberboard

- From Europe, health fashion.

Thermally modified wood technology originated in France, thermally modified wood in France has more than 30 years of application experience, in the 1990s, the use of thermally modified wood decoration France Lyon Opera House.

- Completely natural, green environmental protection.

Thermally modified wood raw materials from natural wood, the production process does not add any harmful chemicals, does not produce any environmental pollution problems, is a real green building materials.

- Safe and durable, anti-corrosion and insect prevention.

Thermally modified wood, due to the destruction of its nutritional components, blocks the necessary nutrient chain of wood decay, so that it has the function of anti-corrosion and insect prevention, and greatly extends the service life of wood. High temperature destroys the nutrients of wood decay bacteria, cutting off the growth of bacteria in the wood from the source, in addition, at high temperature, most of the cellulose and sugar organic matter of the wood itself are decomposed, volatilized, and repeatedly combined with crystallization, thus forming natural resistance, effectively playing the board without insects, insect ants, anti-corrosion effect.

- No delamination cracking, stable size.

Thermally modified wood, due to its water absorption functional group hemicellulose is restructured, so that the product has better physical properties, so that the use of wood performance has been greatly improved, such as water absorption decline, moisture absorption expansion decline, dimensional stability improvement, carbonized wood products will not layer will not crack, extremely stable size.

- Carbonization modification, net aldehyde aldehyde removal.

Deep carbonization without mechanical carbon element can reach more than 50%, its adsorption function is excellent, carbonized plate produces a large number of micropores after high temperature, tar material is excluded in the hole, can produce a good adsorption effect, can effectively adsorb formaldehyde and TVOC volatile organic compounds, reduce formaldehyde and TVOC content, In the air convection, formaldehyde and TVOC can also be effectively dispersed and desorbed, and effectively improve the load rate of indoor ambient air quality, reduce indoor air odor and formaldehyde TVOC allergens.

- Beautiful color, warm and natural, no paint maintenance.

The thermally modified wood core layer is dark brown, the surface natural wood skin texture is clearly visible, and the touch is warm. The surface color is colored by special inorganic mineral pigments, and the heat sealing treatment technology is used to make the color stable for a long time. Later use is completely paint-free maintenance.

WeChat

WeChat